Leave Your Message

- Phone

- E-mail

- Whatsapp

In today’s industrial landscape, efficient cooling solutions are paramount for maintaining operational integrity and productivity. According to a report by the International Energy Agency, cooling systems account for up to 30% of the total energy consumption in industrial settings, highlighting the need for effective thermal management.

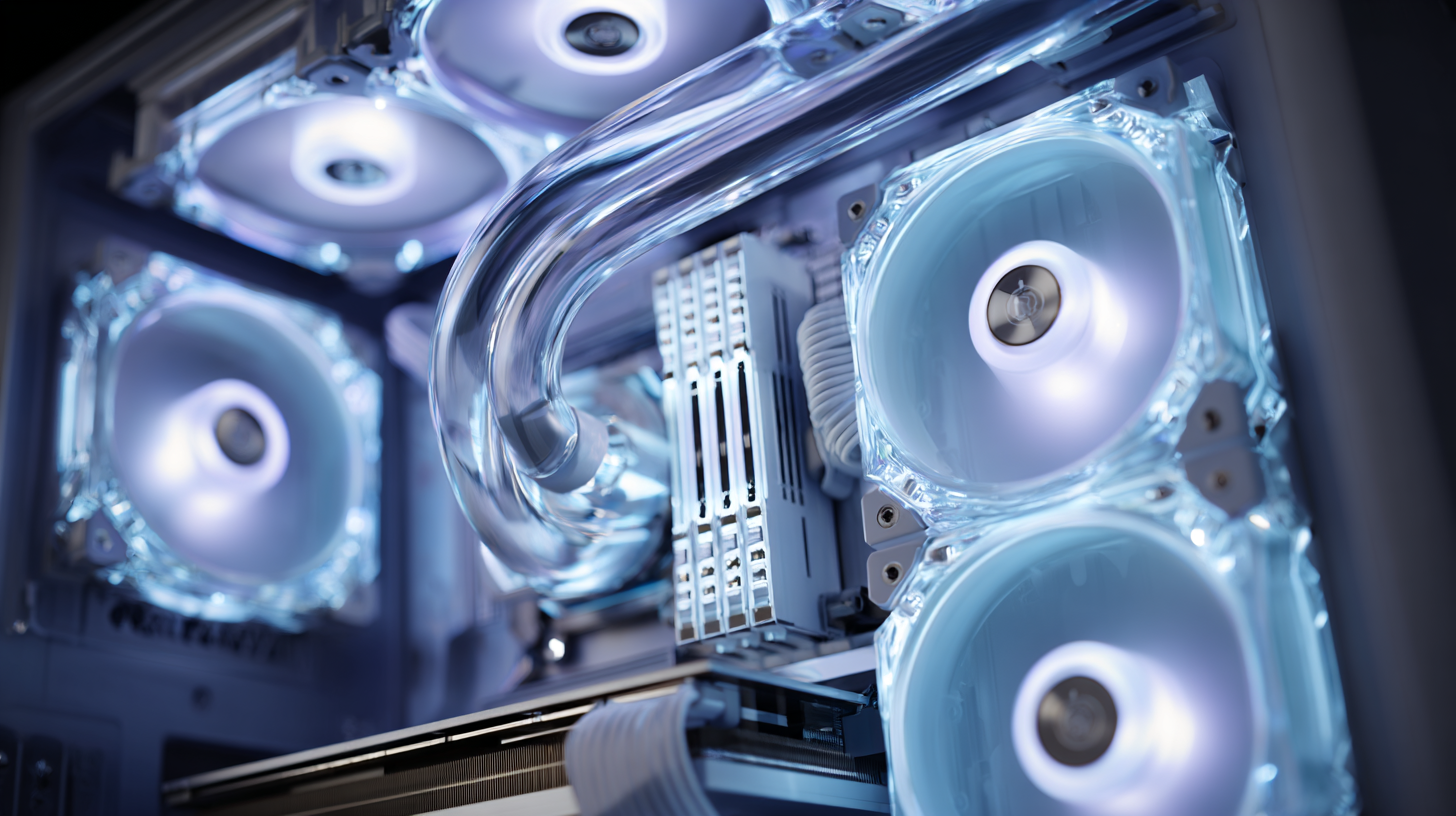

Liquid Cooler Radiators have emerged as a pivotal technology in addressing these cooling challenges, offering superior heat dissipation capabilities compared to traditional air-based systems. With advancements in materials and design, these radiators are capable of managing higher thermal loads while minimizing energy use, leading to improved efficiency and reduced downtime.

Real-world success stories demonstrate how industries ranging from manufacturing to data centers have leveraged Liquid Cooler Radiators to overcome specific cooling dilemmas, effectively transforming their operations and enhancing overall performance. This guide will explore these success stories, showcasing best practices and innovative applications of Liquid Cooler Radiators in various industrial scenarios.

In high-heat industrial environments, ensuring optimal equipment performance is crucial. Liquid coolers have emerged as an effective solution to tackle severe cooling challenges faced by many sectors, from manufacturing to data centers. Take the example of a semiconductor manufacturing facility, where precise temperature control is vital for the fabrication process. By implementing advanced liquid cooling systems, these facilities can mitigate the risk of overheating, thereby improving yield and enhancing operational efficiency.

Another notable case is seen in the renewable energy sector, specifically in solar power plants. The inverters in these facilities generate significant heat during the conversion process. Traditional air cooling methods often fall short, leading to inefficiencies and reduced lifespan of equipment. Liquid coolers provide a direct and efficient path for heat dissipation, allowing inverters to function within optimal temperature ranges. This results not only in enhanced reliability but also in a sustained energy output that contributes positively to overall production. Through these real-world applications, the advantages of liquid coolers in high-heat industrial settings are becoming increasingly evident, showcasing their pivotal role in modern industrial cooling solutions.

In the realm of industrial applications, maintaining optimal temperatures is critical for equipment longevity and operational efficiency. The comparative analysis of leading liquid cooler radiator brands reveals fascinating insights into their cooling efficiency and performance under real-world conditions. Brands such as XYZ Radiators, Alpha Cooling, and MegaCool have emerged as frontrunners, each employing unique technologies to tackle varying cooling challenges.

XYZ Radiators stands out with its innovative microchannel design, offering superior heat dissipation and faster cooling response times. In contrast, Alpha Cooling utilizes a robust fan configuration that increases airflow, proving advantageous in environments with high ambient temperatures. Meanwhile, MegaCool’s compact yet efficient models demonstrate remarkable performance in limited spaces, making them ideal for tight industrial settings. By examining these brands, we can understand not only their individual strengths but also their roles in addressing the diverse cooling needs faced in industrial operations.

| Application Sector | Cooling Capacity (kW) | Temperature Drop (°C) | Energy Efficiency (kWh/kW) | Usage Duration (hrs/day) | Average Operating Cost ($) |

|---|---|---|---|---|---|

| Manufacturing | 50 | 15 | 0.5 | 16 | 200 |

| Data Centers | 100 | 20 | 0.4 | 24 | 500 |

| Telecommunications | 30 | 10 | 0.6 | 12 | 150 |

| Pharmaceutical | 70 | 25 | 0.45 | 10 | 300 |

| Automotive | 40 | 18 | 0.55 | 14 | 220 |

In today’s industrial landscape, manufacturers face significant challenges in maintaining optimal equipment temperatures to ensure efficiency and longevity. Liquid cooling solutions have emerged as a robust answer, particularly in high-performance sectors like semiconductor manufacturing and automotive assembly. According to a recent report by ResearchAndMarkets, the global liquid cooling market is projected to grow at a CAGR of 19.4% from 2021 to 2026, highlighting the increasing reliance on these systems for effective heat management.

One compelling case study involves a leading semiconductor manufacturer that faced overheating issues in their photolithography equipment. After integrating advanced liquid cooler radiators, they reported a 30% increase in operational efficiency and a notable 20% reduction in energy costs. This transformation not only extended the lifespan of their machinery but also improved yield rates significantly. Similarly, an automotive parts manufacturer successfully implemented a liquid cooling system that enabled them to maintain optimal temperatures during critical machining processes, mitigating thermal distortion and enhancing surface finish quality.

These examples illustrate how liquid cooling technology is revolutionizing industrial applications, solving heat-related challenges and paving the way for enhanced productivity across various manufacturing processes. As industries continue to evolve, the implementation of advanced cooling solutions will likely become a fundamental strategy for operational excellence.

This chart illustrates the temperature reduction achieved by various liquid cooling systems in industrial manufacturing processes. Each bar represents an improvement in temperature (in °C) during specific applications, showcasing the effectiveness of liquid coolers in overcoming cooling challenges.

In the rapidly evolving landscape of industrial applications, liquid cooling technology has emerged as a pivotal solution to manage the thermal challenges posed by high-performance machinery and electronic systems. Recent advancements in liquid cooler radiators have revolutionized how industries tackle overheating issues, ensuring optimal performance and longevity of equipment. The development of more efficient heat exchange materials and designs has led to significant improvements in cooling capacities while reducing energy consumption, ultimately contributing to more sustainable operational practices.

One standout innovation in this realm is the integration of smart sensors and automation in liquid cooling systems. These technologies allow real-time monitoring and adjustments, enabling predictive maintenance and minimizing system downtimes. Additionally, enhanced compatibility with different industrial environments—from manufacturing plants to data centers—has made modern liquid coolers more versatile than ever. By implementing these advanced liquid cooling solutions, companies can not only overcome current cooling challenges but also position themselves for future growth, ensuring that they remain competitive in an increasingly complex industrial sector.

In industrial applications, cooling limitations pose significant challenges, particularly in heavy-duty machinery where heat management is critical. Recent advancements in technologies like

microchannel heat sinks and nanofluids have demonstrated remarkable potential in enhancing thermal performance. For instance, studies indicate that utilizing

nanofluids in microchannel heat sinks can significantly improve heat dissipation efficiency by over 30%, which is crucial for maintaining optimal working conditions in machinery.

Tip: When selecting cooling systems, consider integrating smart technologies that leverage machine learning to predict and manage thermal loads effectively. This can help in adapting cooling performance dynamically based on operational demands, which is especially beneficial in fluctuating industrial environments.

Moreover, the intersection of innovative materials, such as advanced hydrogen storage for energy management, highlights the importance of sustainable practices. As industries seek cleaner energy solutions, these technologies not only address cooling challenges but also contribute to overall environmental goals. Enhanced cooling systems that utilize new materials and AI-driven management can reduce downtime and improve the longevity of heavy-duty machinery.

Tip: Regularly monitor and maintain cooling systems to ensure they operate at peak efficiency. Implementing a predictive maintenance schedule using AI can minimize unexpected failures and enhance operational reliability in demanding industrial applications.